OEM Service

Customized from a Current Model

The most effective and efficient way to design a charger catering your specific needs / requirements. Our expertise would get you a best-fit model as the prototype and you can then contribute with specific output power, parameters, dimensions, or other concerning factors including the cost constraints. Our team of dedicated engineers and skillful crew at the factory is always here to help.

Develop a Brand-New Product / Solution

From the original abstract concept, functional and technical features to the exterior mechanical design, we as a team will be your most reliable support and back-up. A careful calculation on the constraints imposed by the enclosure type, the heatsinking method and the magnetic topology together with the overall production cost would determine if your initial PCB-layout successful. Our R&D engineers work close with the crew at the factory to implement and realize your projection.

OEM SREVICE

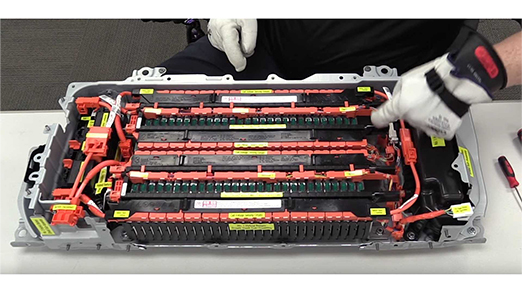

We have thousands of models of the lithium polymer battery and we can provide OEM SERVICE to satisfy customers’ needs.You can contact us by the following procedures:

1.Demand Confirmation

Each custom service reflects the strength of our company. According to customers’ requirements, we can customize various specifications, sizes, thickness, hardness, and special functions. For us, providing the most suitable product that the customer needs is the best. Therefore, we pay great attention to the needs of customers, and try our best to offer the most suitable products for customers.

2.Technical Seminar

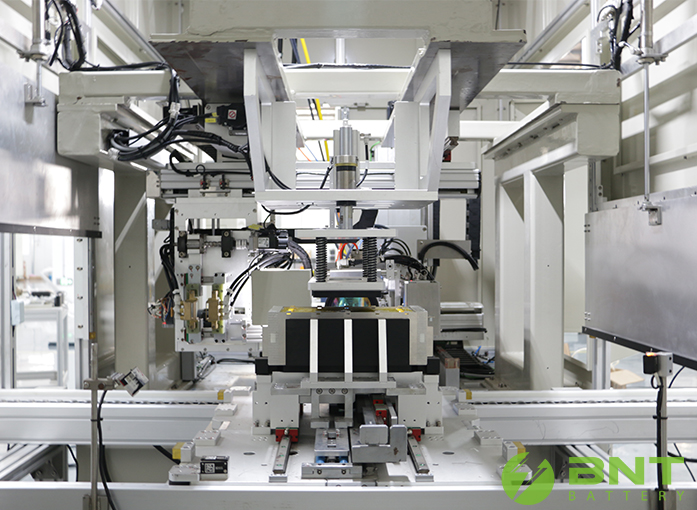

After we know the specification and other parameters needed by the customers. We will organize a technical seminar to determine the feasibility of the special specifications customers want. Our company has excellent technical control team which has many years of practical experience in the field of lithium polymer battery. Team members can accurately control the various process system of batteries, and strictly enforce the production procedure.

3.Proofing And Pricing

We will get a result that whether the production is feasible after the company technical seminar.

If it does not meet the company’s production technical requirements, we will communicate with customers immediately and then discuss product details and solutions. If the customer’s request meets our production requirement, we will offer a proofing quotation to customers for confirmation. Then, we will perform the product production after proofing.

4.Sample Test

After finishing proofing the products, we will test these products.The test indexes include the dimension, voltage, capacity, impedance, weight, cycle times, PCM OCP, NTC, appearance. We have advanced testing machinery to ensure the accuracy of the test data. After the inspection process is finished, we will transport the proofing products to our customers.

5.Mass Production

After the sample is delivered to customers, we will contact them for testing the performance of our product. After getting their confirmation, we will send a formal specification data sheet for them to sign and confirm, then we will start mass production. Our Quality Department will conduct the inspection based on AQL standards.

6.packing And Shipping

The battery is produced according to the customer's request and it must be insulated before

packing. Each battery is placed in specially-made blister tray. We generally do customs

declaration in XiaMen port and ship directly abroad . Large cargo will usually be shipped by sea, and delivery time is about 30-80 days. It usually takes 5-7 days to ship the small cargo.

CONTACT US TODAY ABOUT YOUR PRODUCT AND APPLICATION NEEDS